Wet Attritor Mill/Continuous Attritor

Stirred Vertical Ball Mill Grinding System for particle size reduction in laboratory and production scale.

SANGXING FEIRONG is proud to offer superfine particle reduction grinding attritors. This is continuous attritor mill which has a compact vertical design suitable for continuous production of large quantities of materials.

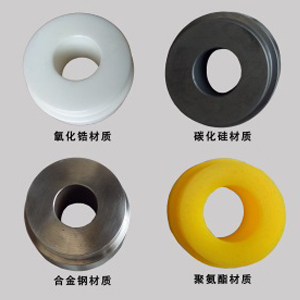

We provide grinding mills for laboratory use with a grinding cylinder volume of 0.5L, but also industrial grinders with a grinding cylinder volume of 100L. The grinding structure of the bead mill and the material of the grinding cylinder can be customized according to the materials that the customer needs to grind, to ensure the purity of the grinding materials to the utmost extent.

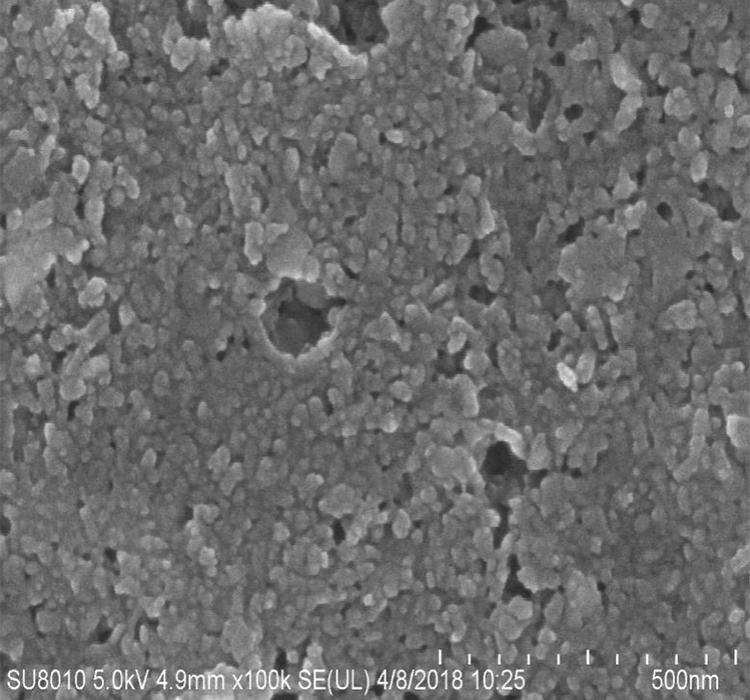

The SP series bead mills can efficiently perform the functions of homogenization, emulsification, dispersion, mixing, shaping, and grinding of materials. It can also grind the materials down to nanometer level.

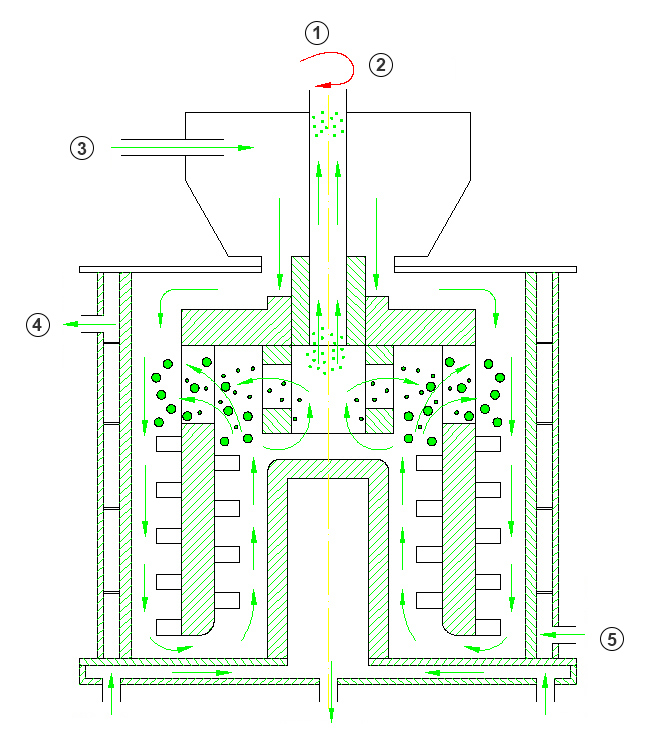

- Discharging

- High speed rotation

- Feeding

- Cooling water outlet

- Cooling water inlet

SANGXING FEIRONG has developed a vertical bead mill without shaft seal and screen to address the problems faced by traditional horizontal grinding attritors, including the leakage and damage of mechanical seals, blockage of separating mesh, difficulty achieving nanometer particle size, non-uniform particle size, and low grinding efficiency. The grinder without shaft seal and screen prevents the leakage of coolant caused by the damage of seals and the blockage of separating mesh for grinding medium as small as 0.1mm, thus realizing nano-scale grinding.

Operating in a continuous mode, the grinding mill sends the material to the grinding chamber through the feed diaphragm pump for grinding. Once fully ground, the material is discharged from the top of the shaft through the discharge diaphragm pump. This attrition mill can realize fractional separation and classified grinding during operation, achieving results with uniform particle size distribution and high energy utilization.

In classified grinding and fractional separation, the whole grinding zone can be divided into inner and outer grinding zones by cooperation of the separation turbine, the agitation rotor, and the inner stator so that large particles can be ground longer and small particles shorter to realize uniform particle size distribution.

- Ceramics

- Inks

- Paints

- Industrial coatings

- Metal oxides

- Bagasse

- Graphite

- Carbon black

- Biofuel

- Catalysts

- Cosmetics

- Ferrites

- Fibers

- Glass Frits

- Metal Oxides

- Metal Powders and Flaking

- Minerals, Coal

- Pigments

- Proppants

- Reaction Milling

- Tungsten Carbides

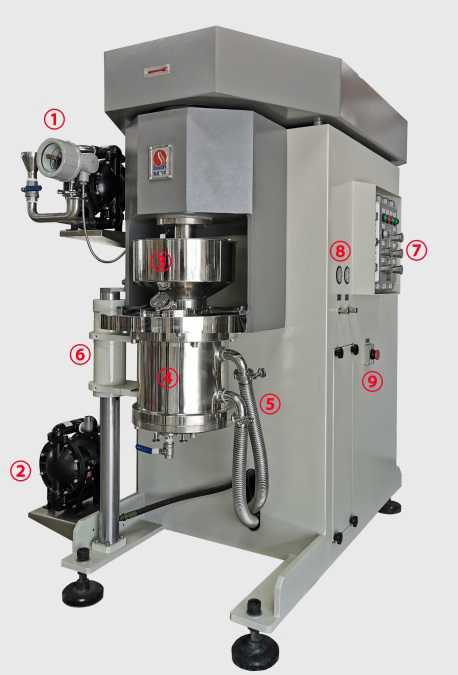

- Thermometer with sensor, and will shut down the machine when the temperature higher than the set value.

- Pneumatic diaphragm pump

- Material hopper:for feeding material and easy to observe.

- Grinding barrel: various volume and parts are optional to meet the grinding requirement of different kinds of materials.

- Solvent and corrosion resistance pipes

- Hydraulic lift device easily remove and install the grinding barrel

- Operation panel: button-type or touch screen operation panel can be selected. The man-machine friendly contact surface, all operations completed on the panel.

- Air pressure knob: adjust the air pressure to control the pump speed.

- Emergency stop button

- With reasonable cooperation of the feed turbine, feed hopper and grinding chamber, the material enters the turbine annular groove along the feed hopper, and then is easily transported by the turbine into the grinding chamber, and the grinding medium does not recoil into the feed hopper, thus achieving closed grinding.

- The structure without shaft seal prevents leakage and damage of the mechanical seal and prolongs the service life of the bead mill.

- The discharge from the top of the shaft and the screen-less design prevents the blockage of the separation mesh.

- There are water cooling system in the grinding barrel, cover of grinding barrel and jacketed stirring tanks to achieve the all-round cooling of the material and improve the grinding effect.

- The vertical structure can realize uniform force, stable operation, and long-term continuous production.

- The mesh-less structure allows the size of the grinding media to be as low as 0.1mm for nanoscale grinding.

- The structural parts and grinding chamber materials can be selected according to material characteristics.

| Model | Volume (L) | Power (kW) | Motor speed (rpm) | Flow (L/h) | Bead diameter (mm) | Bead content (vol. %) | Dimensions (mm) | Weight (kg) |

| SP-0.5 | 0.5 | 2.6 | 2500 | 20-40 | 0.1-1.0 | 65-80 | L650×W632×H807 | 130 |

| SP-1.5 | 1.5 | 7.5 | 1461 | 80-100 | 0.1-2.0 | 65-80 | L1160×W933×H1502 | 590 |

| SP-5 | 5 | 18.5 | 1470 | 200-300 | 0.1-2.0 | 65-80 | L1472×W1122×H1773 | 1230 |

| SP-15 | 15 | 37 | 1482 | 400-600 | 0.1-2.0 | 65-80 | L1604×W1257×H2032 | 1720 |

| SP-30 | 30 | 45 | 1484 | 600-1000 | 0.1-2.0 | 65-80 | L1765×W1327×H2242 | 2300 |

| SP-60 | 60 | 75 | 991 | 1200-2000 | 0.1-2.0 | 65-80 | L2165×W1590×H2255 | 4900 |

| SP-100 | 100 | 132 | 991 | 2500-5000 | 0.1-2.0 | 65-80 | L2271×W1690×H2373 | 5100 |

-

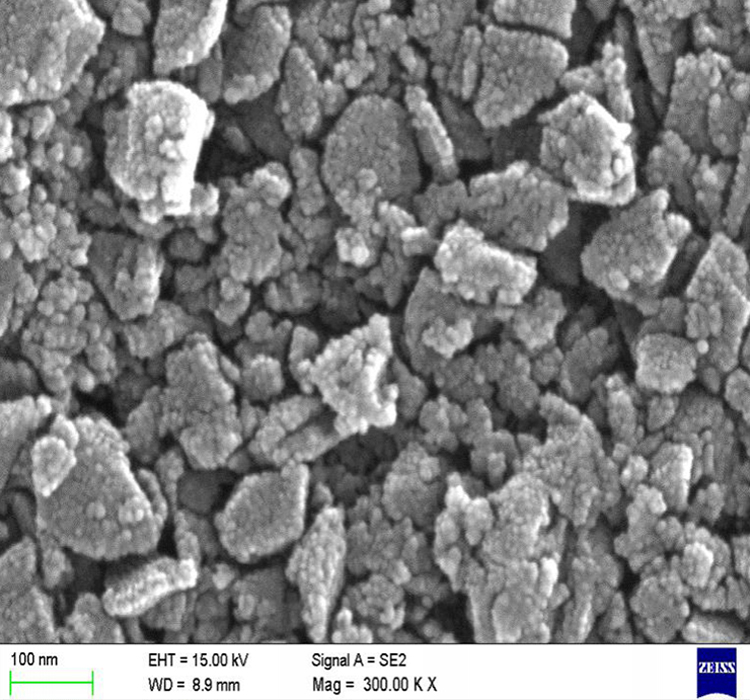

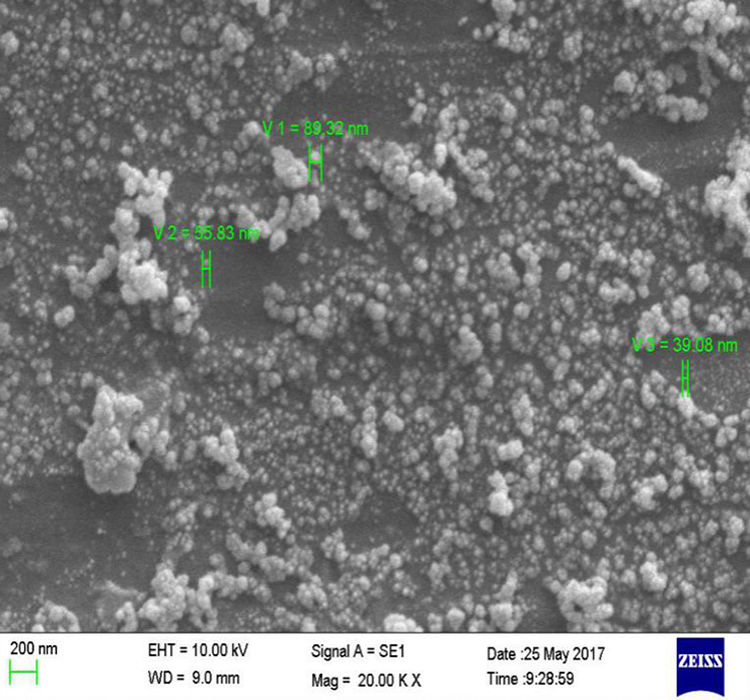

- Grind the silicon carbide particles to 32nm

-

- Grind the diamond particles to 35nm

-

- Grind the magnesium to 39nm

-

- Operation panel

-

- Touch screen

-

- Temperature gauge

-

-

-

Different cylinder materials are available: polyurethane, alloy steel, zirconia, and silicon carbide.

Request a Quote? Feel free to contact us at any time!

click here