Paint Grinding Application

Superior paints and coatings production solutions

Dyes are primarily organic compounds that give other materials a bright color. Pigments used today are usually called synthetic dies as they are artificially synthesized. Dyes and pigments are usually self-colored compounds that offer a bright, fast color to other substances in a molecular or dispersed state. e mostly organic compounds that impart bright and fast colors to other materials. Paint refers to any pigmented liquid, liquefiable or mastic composition that forms a thin film after application for protective and decorative use. The particle size is an important dye performance indicator and is usually increased by the manufacturer through a grinding process. The finer the paint, the stronger the adhesion. The smoother and finer the film appearance, the less dye consumption is utilized.

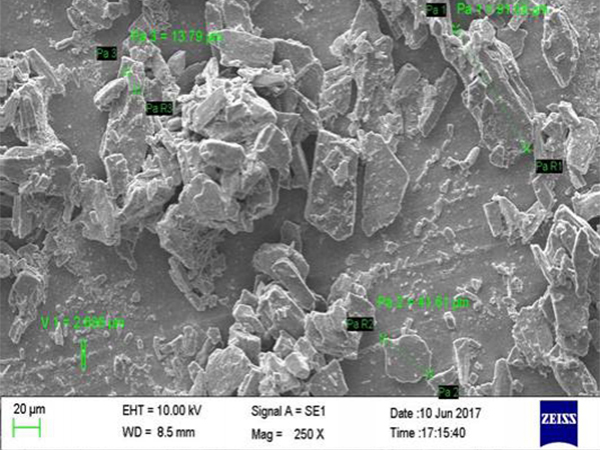

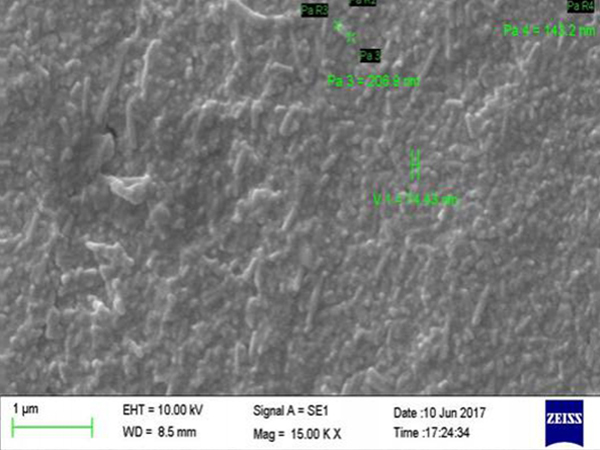

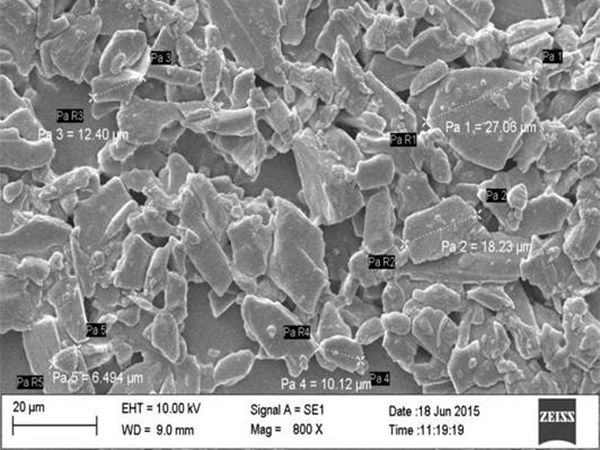

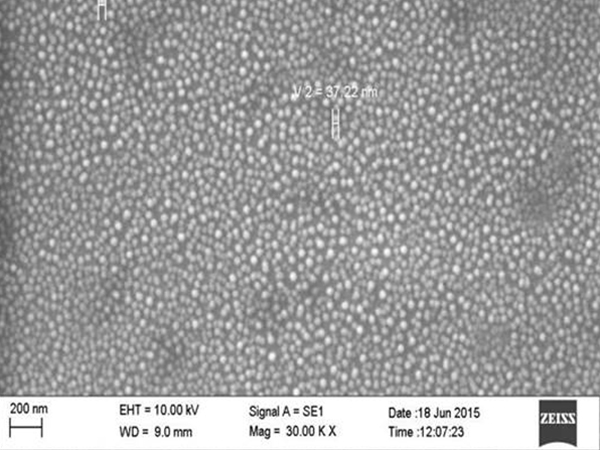

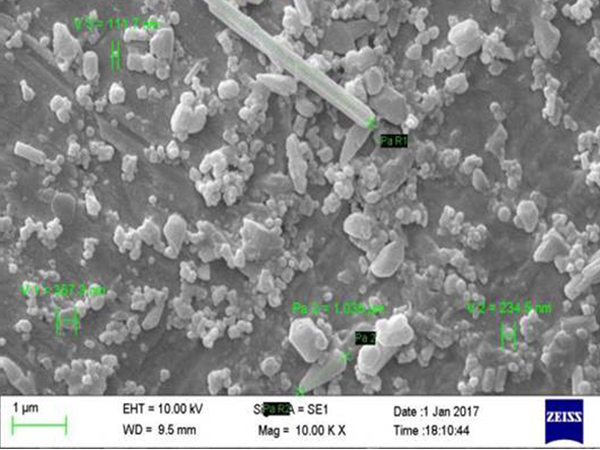

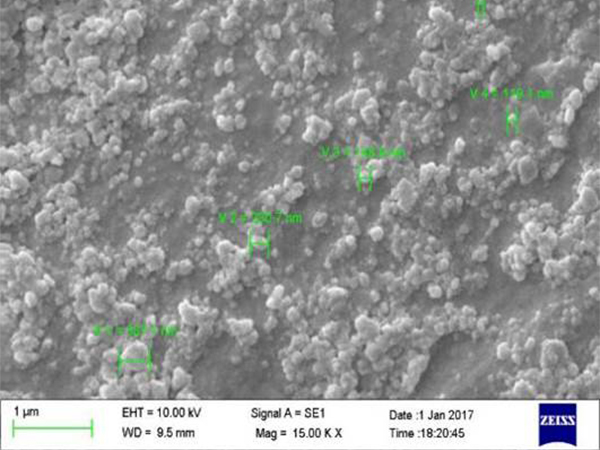

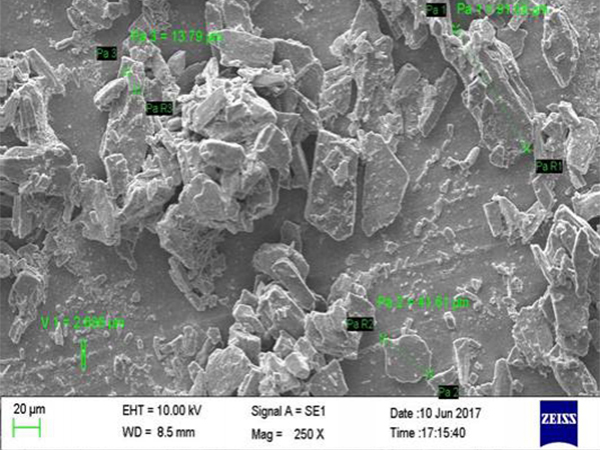

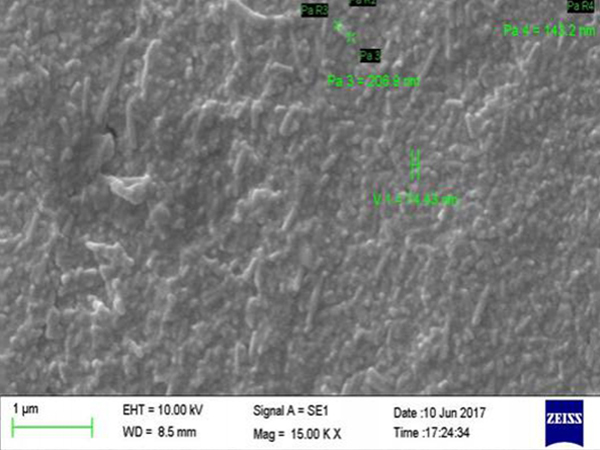

Shown here are the results of ultrafine paint grinding using our grinding mills. It is clearly indicated that ultrafine grinding using our equipment achieves a significantly reduced particle size and more uniform distribution, effectively improving paint performance and offering higher economic benefits.

Grinding of water-based dye

-

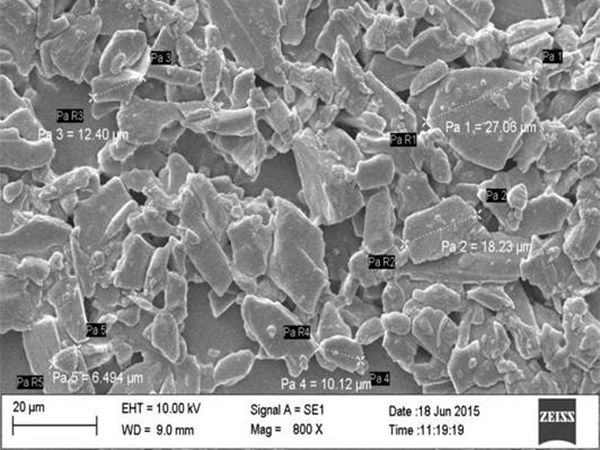

- Before grinding

-

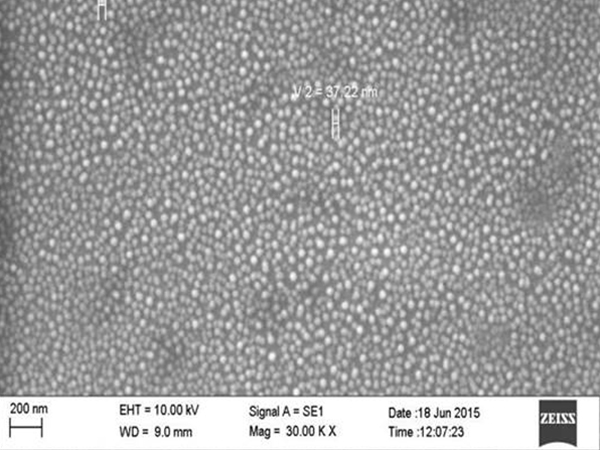

- After grinding

| Characterized size | Feed | Products |

| D50(μm) | 30.70 | 0.15 |

| D90(μm) | 81.00 | 0.30 |

Grinding of water-based digital inkjet

-

- Before grinding

-

- After grinding

| Characterized size | Feed | Product |

| D50(μm) | 18 | 0.04 |

| D90(μm) | 31 | 0.05 |

Grinding of water-based pigment paste

-

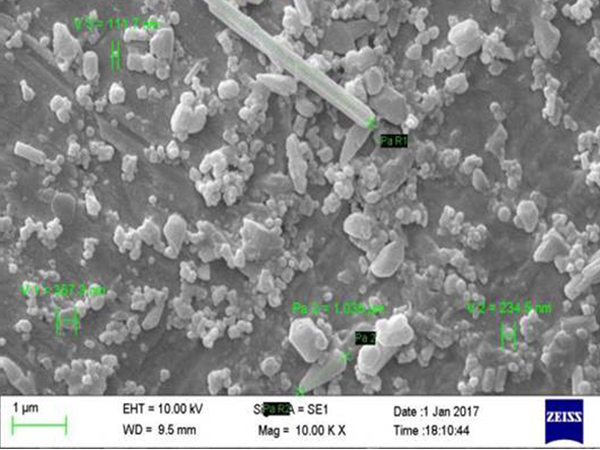

- Before grinding

-

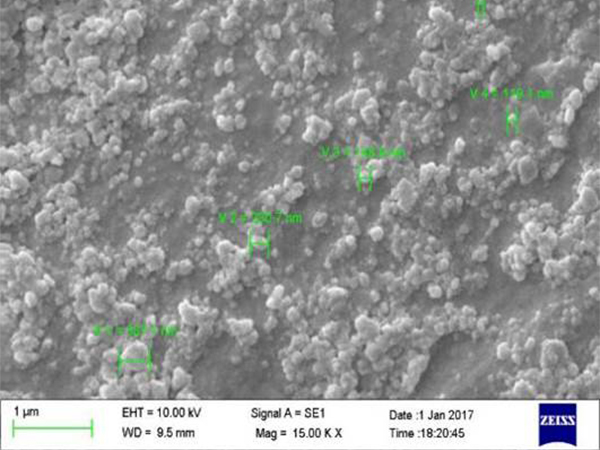

- After grinding

| Characterized size | Feed | Product |

| D50(μm) | 1.2 | 0.08 |

| D90(μm) | 2.2 | 0.15 |